MPE MANN Refinery Naphtha-Hydro Desulfurization Plant Commissioning and PGTR with NOVATECH Process Equipment Pvt. Ltd.

Location: Onshore-Thanbayakan, Myanmar

Design Capacity: 5000 BPSD Treated Naphtha Rundown System

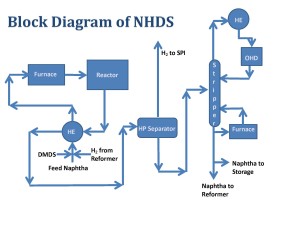

The main purpose of Naphtha HDS Unit is to clean-up the Naphtha, i.e. to remove Reforming Unit Catalyst Poison, from straight run Heavy Naphtha from the Topping Complex prior to sending to Reforming Unit. Sulfur content is brought down to 0.5% making it suitable as Feed charge to Reforming Unit. Especially Sulfur is converted to Hydrogen Sulfide (H2S) by Hydrogen and then the Hydrogen Sulfide can be removed relatively easily. Naphtha HDS employs and select catalyst and Hydrogen rich Gas to decompose organic sulfur, oxygen and nitrogen compounds contained in Naphtha. In addition the Unit decomposes organometallic compounds and saturates olefinic compounds.

UPCEM Scope: Pre-Commissioning, Commissioning & Handover Management for complete project and Commissioning Manpower Supply.

Process Equipment’s in NHDS Unit consist of broadly the following:

- Surge Drum

- Charged Pump

- Preheater (Shell & Tube heat exchanger)

- Charge Heater (Furnace)

- Reactor

- Three Phase HP Separator

- Stripper Tower

- Reboiler(Furnace)

- Cooler (Shell & Tube heat exchanger)

- O/H Drum (Separator)

Process Facilities in NHDS Unit consist of broadly the following:

- Industrial water

- Cooling water

- Nitrogen

- Utility air

- Instrument air

- high pressure and Low pressure steam

- Fuel gas

Design of the unit is licensed by AXENS