MPE MANN Refinery Coking Plant Commissioning and PGTR with NOVATECH Process Equipment Pvt. Ltd.

MPE MANN Refinery Coking Plant Commissioning and PGTR with NOVATECH Process Equipment Pvt. Ltd.

Location: Onshore-Thanbayakan, Myanmar

Design Capacity: 5200 BPSD of Topped Crude

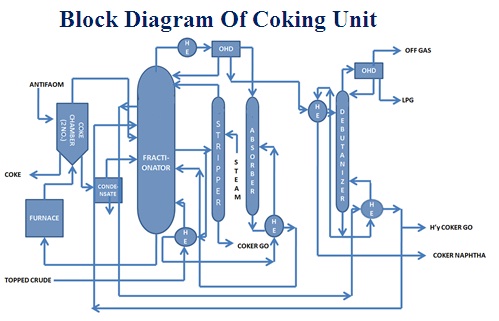

The Coking unit is used to convert topped crude into coke, light coker GO, coker GO, coker Naptha, LPG and Fuel Gas.It is so designed as to yield the maximum amount of cracked distillates while producing a coke suitable for anode production.

UPCEM Scope: Pre-Commissioning, Commissioning & Handover Management for complete Project and Commissioning Manpower Supply.

Process Equipment’s in Coking Unit consist of broadly the following:

- crude charged pump

- Fractionator column

- Three Phase Separator

- Coke chamber

- Crude charge fired heater(Furnace)

- Gas oil stripper

- off gas Compressor

- Absorber column

- Debutanizer

- Shell and Tube heat Exchangers

Process Facilities in Coking Unit consist of broadly the following:

- Industrial water

- Cooling water

- Nitrogen

- Utility air

- Instrument air

- high pressure and Low pressure steam

- Fuel gas